Anti-Glare, Dust & Air Proof

Operator Panel

Aselkon's truck mounted mobile cranes have the largest cabins in Turkey and offer the user a high level of comfort and ease of use. The wide design of the cabins provides operators with more room for movement, while the interior structure equipped with ergonomic details creates a comfortable working environment for long hours. Durable and functional, these cabins can be used even in harsh conditions without any loss of performance.

Electronic Control System

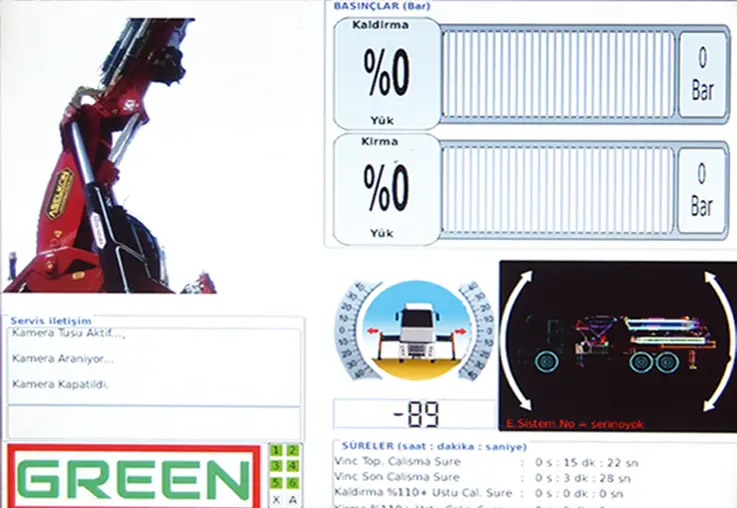

Crane Operator Control Panel has 12.1'inch size, dust and waterproof, anti-glare LCD display, double-sided metal case system. The weight control system to be installed records how long the crane boom has been running. These records can be transferred to the computer via USB, so that the maintenance time and wear statistics of the crane can be calculated. All electronic parts of the crane have IP67 resistant glass. The optimizing device operates on sloping ground with nine axis three-angle sensors (main boom, folding boom and second break) and an electronic balance system.

The pressure and angle of the boom can be monitored on the real-time display.

Dual angle & night vision motion monitoring camera system allows monitoring from the operator panel. Image processing software helps the operator with virtual lines on the screen. ASELKON Visual Guidance System is available for sensitive loading.

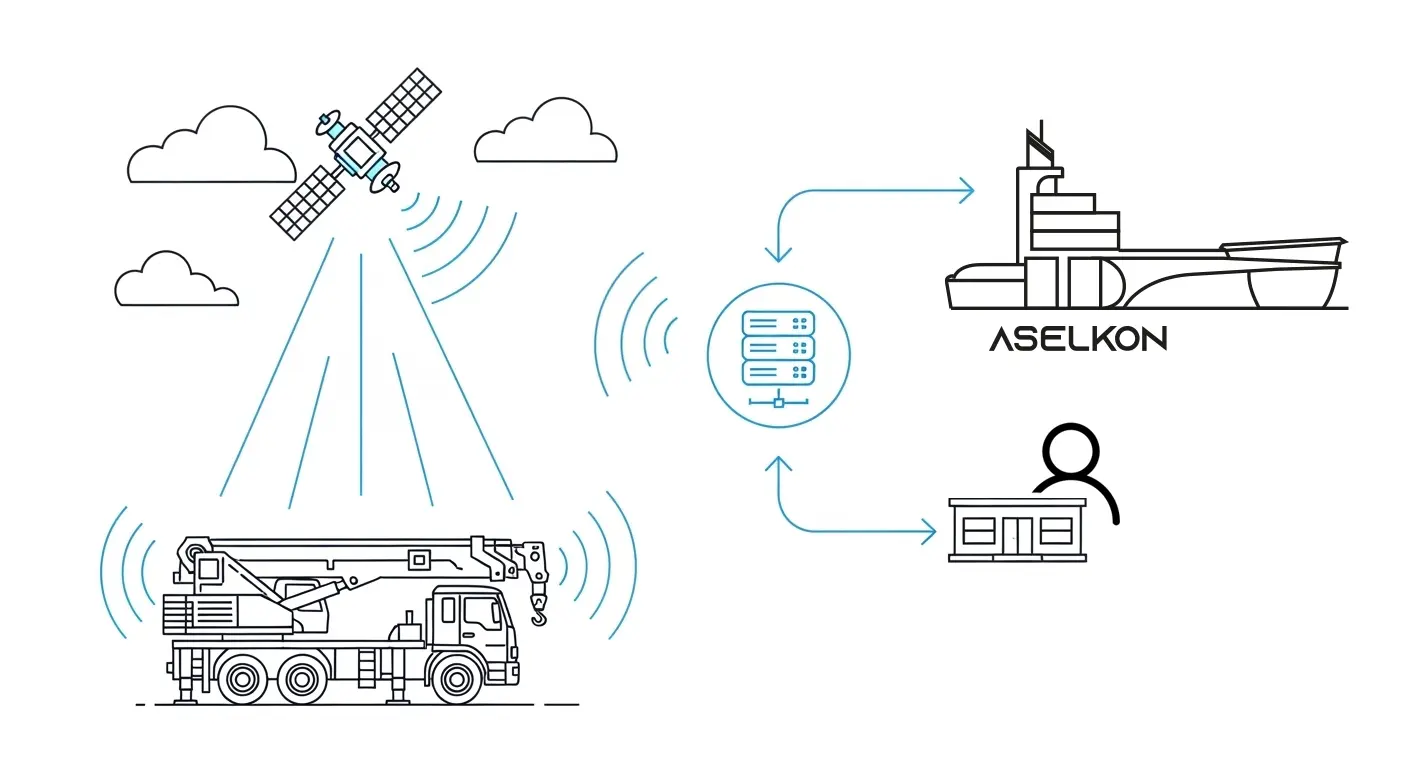

Through the satellite GSM-GPS system, daily, weekly and monthly operation reports can be monitored, ASELKON Maintenance Center sends weekly and monthly operation graphs and GPS map tracking summaries to the machine owner.

Completely wireless, no need to recharge for years, embedded battery, second boom pressure and angle status receiver system.

A multimedia video system showing how to use the crane, including training, maintenance and demonstration videos with subtitles in English, Russian and Arabic.

Overloading is interrupted by an instantaneous control system (Optional Safety System), which only allows the operator to retract the extension booms.

There is an emergency stop button to stop the hydraulic circuit in case of emergency when the operator cannot see it.

Electronic System Software has 4 language options: TURKISH, ENGLISH, RUSSIAN, ARABIC.

Electronic Control System with LCD Display

When the crane starts to operate, you can access the main page on the LCD screen. load lifted at the boom tip is displayed instantaneously with percentage and pressure value. Also total and last working hours, load and pressure values on the cylinders are recorded and stored statistically. This data is transmitted through the system easily transferable via mailso that maintenance and performance monitoring becomes more efficient.

Advanced 9-axis balance system thanks to which the working angles are shown to the operator in detail in the X-Y plane. This feature is both provides high security and supports the operator to use the crane at optimal angles.

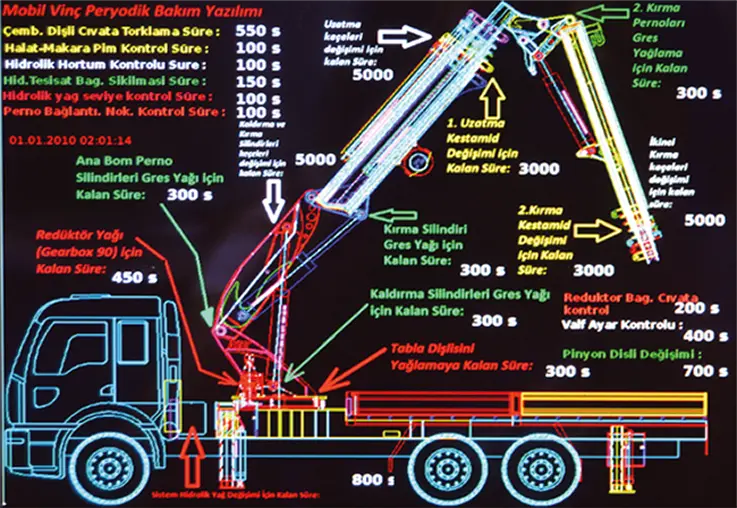

Smart Maintenance

Follow-up

System

Thanks to the digital display integrated on the cranes, counting down according to working hours and easy tracking of maintenance operations (lubrication, filter change, etc.) presents. From the screen, the operator can see the time left to maintenance in hours and plan accordingly. Also the system showing overdue maintenance as a warning helps to prevent possible failures and ensure that the crane always operates at maximum efficiency.

Wireless Motion Camera System at the Boom End

Developed for maximum safety and efficiency in crane operations wireless motion camera system integrated into the boom tipexpands the operator's field of vision. Located in the cab high resolution LCD display the movement of the load and the working area can be monitored instantly. This eliminates blind spots and makes loading and unloading operations much safer, faster and more precise. This system provides great convenience to the operator, especially in tight spaces and sensitive lifting operations.

Remote GPRS Tracking System

Your cranes working in the field location, working hours and performance statistics you can follow instantly. The system regularly analyzes the collected data forwards via mailThis gives you the opportunity to remotely check the utilization status of your cranes and manage your operations more efficiently.

Global Location Reporting & Operating Frequency Reporting System

Your cranes track its location and frequency of operation with instant reports. You are always in control for safer operations, easy maintenance planning and maximum efficiency.

Fully Wireless Pressure Measurement System

Pressure values on the crane measure instantly and monitor on the screen without the need for a cable. Ensure maximum efficiency with safer handling, fast installation and minimal risk of failure.

Work Summary Report System

It is a system that automatically records and summarizes the daily and weekly working data of the operators in Aselkon cranes. Crane usage times, movement frequencies and operation details are reported to facilitate performance monitoring and maintenance planning.

Unlimited Memory Recording System

It is the system that stores all operation data in Aselkon cranes uninterruptedly and long-term. Past movements, performance data and operation records are stored unlimitedly, enabling analysis and reporting.

Night Vision System with Virtual Range Lines

It is a system that ensures safe operation in Aselkon cranes at night or in low light conditions. Thanks to the virtual range lines placed around the crane, distance and position tracking is done clearly, helping to prevent accidents.

High Quality Parts

All mechanical and electronic components used in Aselkon cranes are manufactured and rigorously tested according to high quality standards to ensure long life and superior performance.